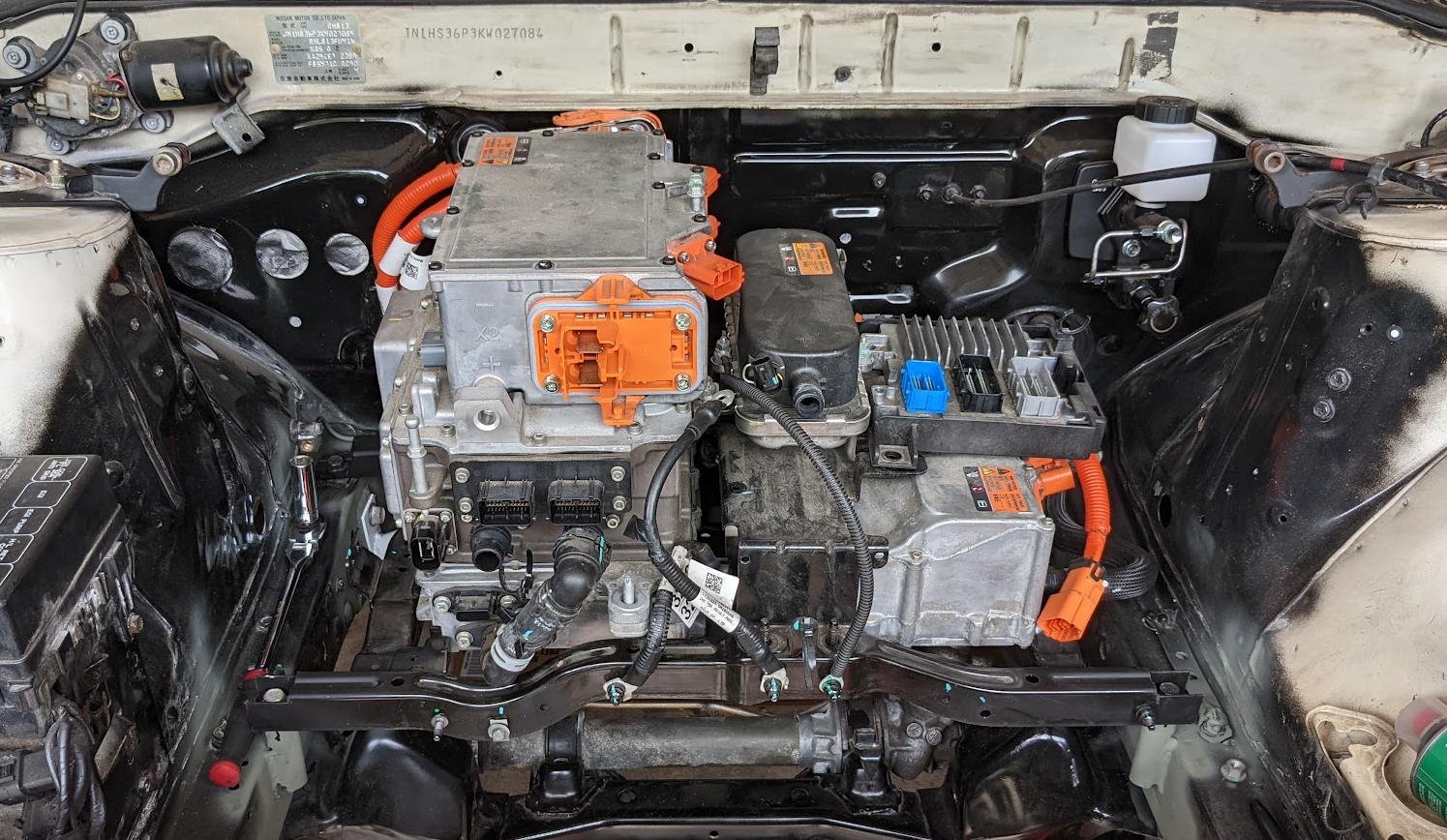

Power Electronics

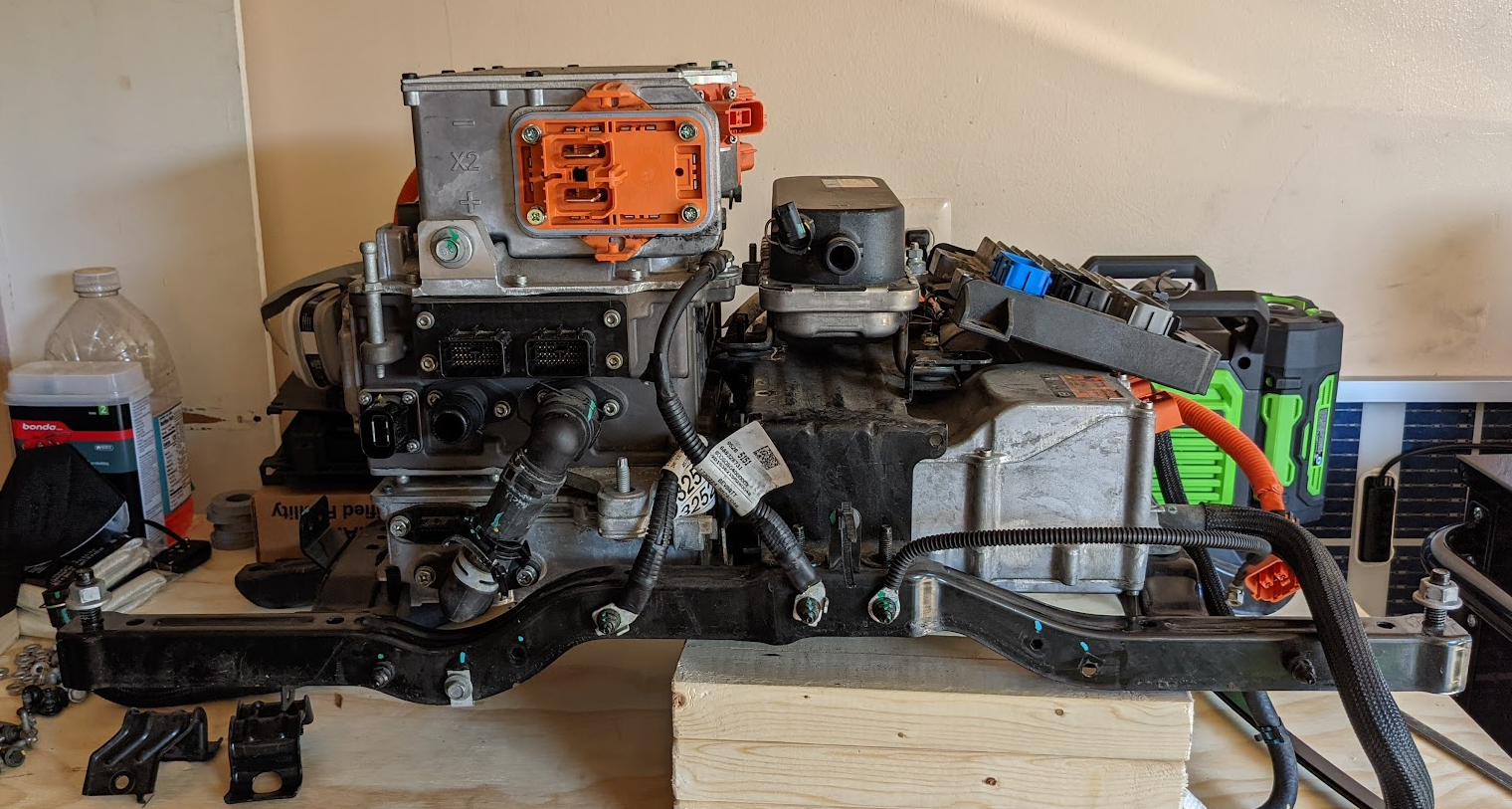

The Spark’s power electronics mount to a lightweight steel sub-frame.

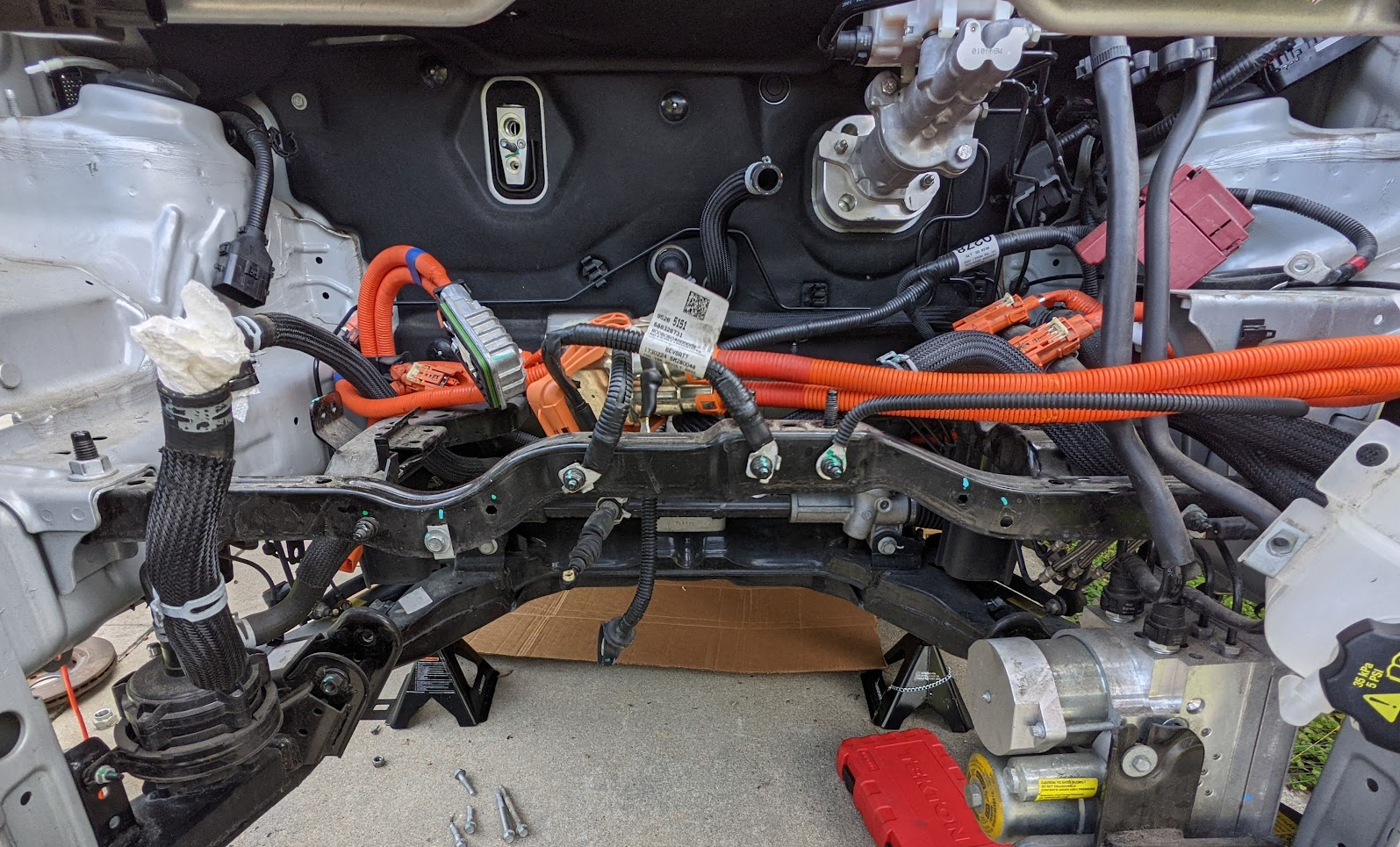

The sub-frame has 4 mounting points and many grounding studs.

Relatively few modifications were required to fit the sub-frame into the 240sx chassis.

-

The front arms were shortened to fit within the skinnier engine bay.

-

The rear arms, which sloped downwards, were cut off and replaced with square tubing.

-

Some material was removed to add clearance to the motor assembly.

-

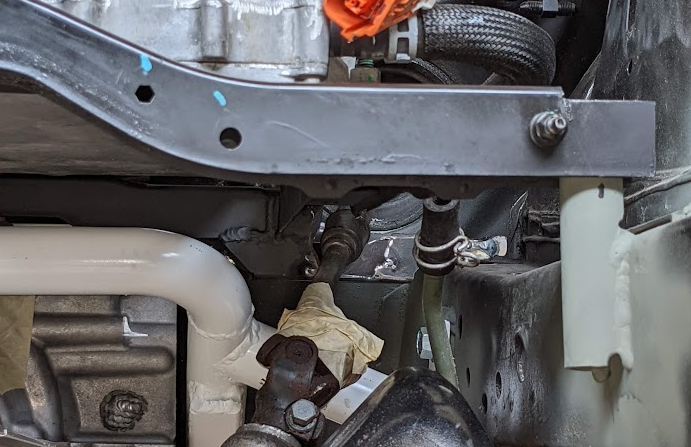

Material was removed to add clearance for the steering column.

To secure the rear mounting points of the sub-frame, M10 nuts were welded directly into the top of the frame rails. The front of the sub-frame fastens to M10 nuts which were welded to posts fabricated from round tube scrap.

The stacked sheet metal which makes up this part of the frame rails was once again painful to weld to. The expansion between sheets caused molten metal to burst out and melt through multiple layers of clothing.

Once the sub-frame was fastened to the chassis, the power electronics were quick to install.