Project Background

This project is an attempt to turn a 1989 Nissan 240sx into an electric vehicle that meets the following goals:

-

Maintains the original handling characteristics by not significantly changing weight or weight distribution.

-

Has enough power to feel fast, but still be drivable at full throttle without electronic assists.

-

"It’s more fun to drive a slow car fast…"

-

-

Can slide around easily.

-

Gets me to work and back: at least 50 miles of range, ideally at least 70.

The Car

I bought this 240sx in 2016. It was mostly stock except for suspension components, and it had a 5 lug swap with 300zx brakes.

I quickly fell in love with the interior. Like most 90s Japanese sports cars, the dash flows smoothly into the doors and center console. The low dash and many windows yield great visibility. The seats and design elements are reminiscent of a spacecraft.

The stock KA24E motor is a bit slow, making ~130HP from the factory. A cheap turbo kit was recently released for this motor, so I decided to learn how to turbo the car with it.

The Turbo Experience

The car began to idle poorly on startup, which led me to purchase a Megasquirt PNP2 ECU to help with diagnostics. This was great because it gave me the opportunity to learn how to tune an engine. This was terrible because it is challenging to properly tune across all ambient temperature conditions for cold starts, hot starts, and normal operation.

If I was to tune an engine from scratch again, I would rent a dyno for a few hours and buy an ECU that supports long/short term fuel trims.

I ultimately spent ~$12k replacing all the mechanical components from the original turbo kit, fixing melted components, preventing future plastic liquefaction events, adding supporting mods, and ultimately replacing the turbo itself.

All this work gave me an excuse to buy decent fabrication equipment.

Two years after installing the new turbo, I realized it was time to go electric. The maintenance of a 32 year old heavily modified engine was a chore, and the poor emissions conflicted with my desire to reduce my impact on the environment.

The EV Conversion Plan

I bought a fully working 2016 Chevy Spark EV as the donor car for this project.

The Spark was desireable because the motor is designed to operate at lower RPM. The Spark’s differential gear ratio is 3.8:1, which is very similar to the 4:1 ratio in the 240sx’s limited slip differential. The battery is also relatively small and contains 6 modular cells.

The Spark is a compliance car for GM. It was only sold in a few states, and only from 2014 to 2016. This is why I ended up buying one in fully working condition. There were not many other options.

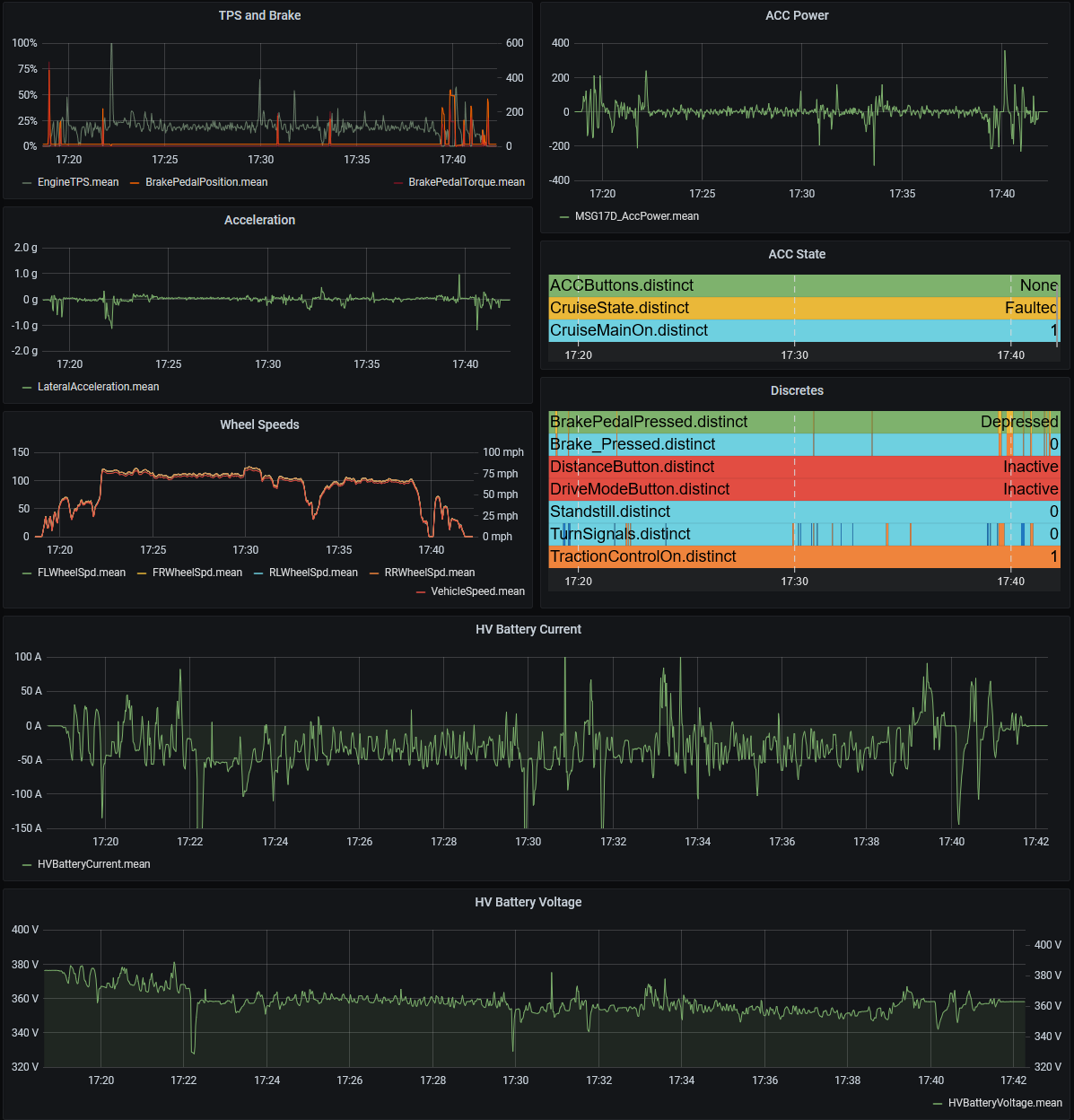

I also wanted to be able to log data from the CAN busses while the car was operating normally. This will help later on as I debug and spoof components that I will not be transferring to the 240sx. Relatively complete CAN DBC files are available from Comma AI’s OpenDBC repo. I used these DBCs to decode CAN messages recorded on a drive home from work. These decoded messages are now stored in InfluxDB for quick visualization in Grafana.