Batteries

The OEM battery back is too bulky and oddly shaped to fit into the car as-is. The entire pack needs to be disassembled and split into two sections to fit in the 240sx chassis.

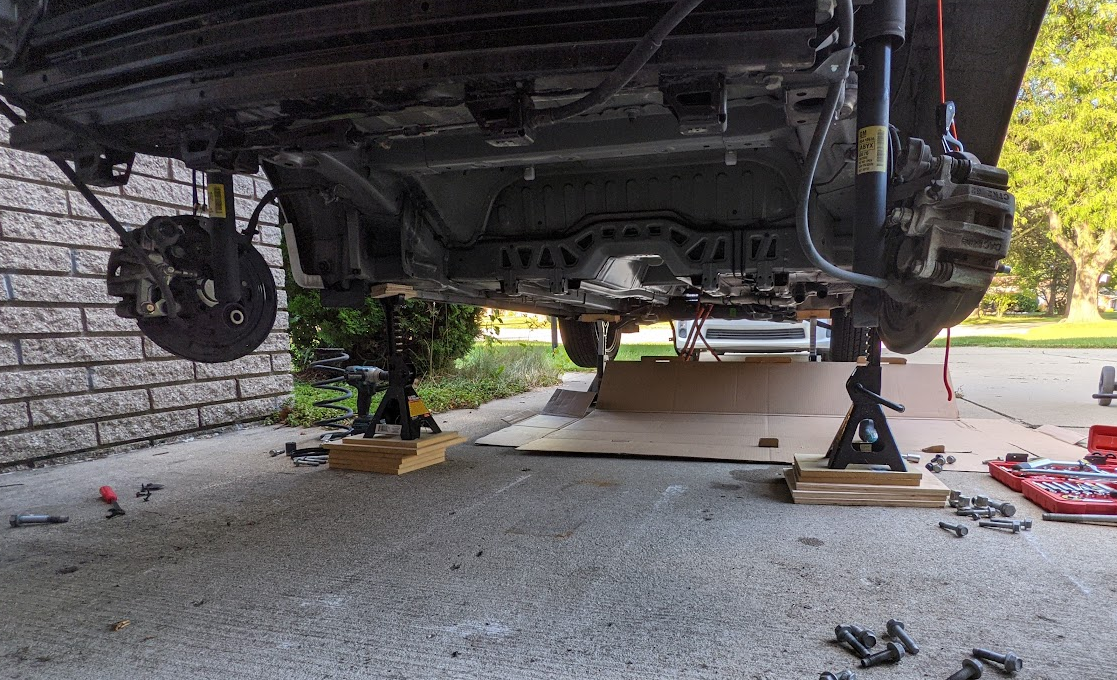

All the rear suspension needed to be disassembled to remove the battery pack from the Spark. This vehicle was not designed with quick battery swapping in mind…

After removing the top lid, the contactor assembly (left), BMS (mounted to cell 3), battery disconnect (above cell 2), water cooling assembly, and the 6 cells are revealed.

Material Choices

The OE box is made out of a plastic/fiberglass composite with steel supporting structures. A thick adhesive is used to waterproof all the steel/composite junctions.

For the custom battery box assemblies, I decided to use 20 gauge sheet steel with 1/2" 16 gauge steel square tube for structure. Aluminum tread plate was another option, but the original battery box already had connector faceplates laser cut out of steel, and I wanted to reuse those.

To electrically insulate the interior, fiberglass can be secured on the inner sides of the box.